Body ConstructionThe E.R.A. fiberglass body is carefully hand-laid with the finest materials and is delivered in black gel coat. High temperature "iso" tooling resin is used throughout. The heat distortion temperature of our resin is 220 F - (standard polyester resin: 190 F, vinylester: 210 F. When you realize that the engine compartment temperature can reach 200 F plus, it becomes clear why we chose this resin over the other alternatives. We use random strand mat for all our panels to prevent cloth pattern print-through. This makes the body a bit heavier than some, but it will maintain an excellent surface finish for many, many years. |

|

|

|

Structural DetailsFiberglass is a wonderful material for low-production manufacturing, but it has a flaw: It has a poor memory - Pressure on it for an extended period of time will distort it slightly. While you won't be able to feel it, the distortion will be visible under a good paint job. E.R.A.'s design has taken all the stress off the outside body. |

The the factory installed intermediate panels buffer the stresses of supporting the body shell. They bond only to the hidden return lips of the outer body at the top of the radiator opening, the front, side and rear edges of the hood, the dashboard and rear cowl area and the front and rear edges of the trunk. The aluminum wheelhouses are riveted to the inner panels and the chassis. The edges seal against the outer shell with rubber bulb-type weatherstripping. |

|

Click here for details (from the manual) on how the body is mounted on the chassis. |

|

Our Fiberglass

On every piece, a gel coat is sprayed into the mold first to create a smooth, void-free surface finish. The outside shell is constructed by first hand applying single layer of 3/4 ounce mat over the entire surface to have better control over surface air bubbles. After it's stabilized, the balance is carefully hand laid to a thickness of 3/16" ot 1/4". The important factors in a body are uniform thickness and high fiberglass/resin ratio. Once the body is well cured, we remove it and trim the cowl, wheel and door openings, plus the holes for the lights.

We make three inner panels that fit between the Once the main shell comes out of the mold, the inner panels are bonded to the return edges of the outer shell. Foam rubber gaskets are used to seal between the inner panels and the outer skin to keep the elements out. This special technique eliminates print-through, waviness and stress cracks on the outer body surface. We want an E.R.A. body to look as good after years of use as it does when it's new. To the best of our knowledge no E.R.A. body has developed a single stress crack from normal use, even after 20+ years on the road.

The inner panels are fastened to the chassis by bonding and riveting. This special technique results in a solid, rattle free semi-unitized structure. Removal of the engine and transmission is still very easy. This car is designed to be servicedwithout removal of the body.

The Doors

|

Like the main body shell, theE.R.A. doors

shells are unstressed.

There is a continuous steel support structurefrom the heavy duty door hinge - mounted on the chassis - to the door latch - also mounted on the chassis. All our interior panels (except for the footboxes, which are fiberglass like the original) are aluminum. We don't use a "tubbed" body. Only the inner fiberglass shell is attached to the steel structure, so that the outside skin remainins stress free. Result: No sag or mis-alignment from fiberglass "creep". |

|

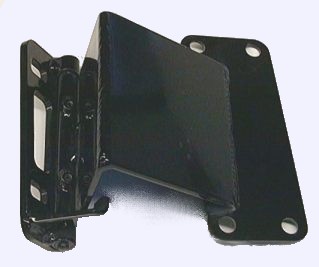

Our door hinges are heavy-duty units capable of keeping our steel-lined doors very secure!

Alignment is accomplished by the use of slotted holes and shims where they bolt to the chassis.

The door hinge also has a stop built in to prevent the door or hinge from hitting the body when it's opened. |

|

Every hinge, both door, hood and trunk, is powder-coated so you don't have to!.

OiliteTM bushings are used at the hinge pivot - there is no steel-to-steel contact and , because we ream-fit the pin to the bushing, the door will will have minimum play. |

|

Our hinge boxes place the pivot point of the hinge very close

to the outside skin, but not touching. This gives maximum edge clearance when the trunk is

opened or closed. We do the same thing with the doors.

The hood and trunk lid are two piece: An outer skin and a finished inner panel carrying the hinges and latches. Because the hinge isn't attached to the outer skin of the body, there will never be print-through. The inner and outer panels are bonded together with special non-shrink epoxy filler.

In other words, our bodies will stay |

|

|

The hinges of the hood and trunk

lids are attached to the inner panels only, with nut plates for attachments built

in.

Our fiberglass footboxes are two inches longer than the original car for more leg room than any standard wheelbase Cobra replica. They attach directly to the tubular steel frame extensions, as original. The rear bulkhead (with removable access panels) and side interior panels are aluminum and attached to the frame as original. Of course we also supply automatic hood and trunk props with the kit. |

|

The original brake cooling ducts are converted to driver and passenger fresh air vents. All hoses, valves and controls are included.

Rear Bulkhead Panels

|

E.R.A. uses aluminum

floor, side fillers and rear bulkhead panels that attach directly to the chassis like the original

roadster. To service the standard Jaguar inboard brakes, the lower bulkhead panel is removable: We

attach the carpetting permanantly only at the top. The lower section is retained by snaps.

For authenticity, we have left the roll bar exposed behind the driver's seat, unlike most other kits that "simplify" their design with a flat panel. And, of course, the seat belts and shoulder harnesses all have their mounts integrated into the chassis. The aluminum tunnel is removable for servicing the transmission and clutch, fastening to the floor and footboxes as the original did. |