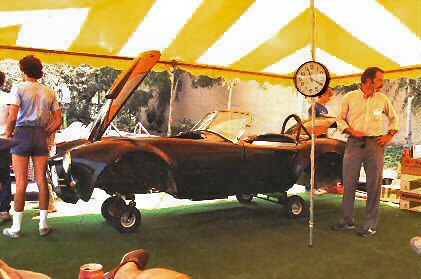

Building a completed car | |

| We arrived with a standard kit, engine and transmission ready

to install,

and a complete rear end (just as we offer as an option). We

also brought

a couple of compressed air cylinders in case we didn't have access to

electricity. We used the dolly wheels* to support the kit

during most

of the construction: It raises the kit to just the "right"

height for

construction.

Typically, we ship the kit on the same dolly wheels that we assemble the kit on. For a modest deposit you can keep the wheels as long as you wish. When you're done, return 'em for a full refund. |

|

If you have limited time, E.R.A.can powder-coat the chassis and small parts, and install the floors, footboxes and body for you. Then you can skip directly to wiring, interior, and installing the engine and transmission and suspension |

| We removed the doors, hood and trunk

lid, then the front and

rear bumpers.

We also removed the rear bulkhead pieces and the tunnel.

The top radiator mount and fresh air vent hoses were disconnected. Then we removed the body, which was fastened to the chassis with sheet metal screws in many places. |

| The footboxes and pedal assembly were then removed. Then, it was quite easy to bond and rivet the aluminum floors to the frame. |  |

|

The engine and transmission were then installed as a

unit.

The rear suspension is also installed. There are only 4 bolts securing the unit, so this operation takes less than 1/2 hour. |