The ERA 289FIA Body

| The

E.R.A. fiberglass

body is carefully laid up

with the finest materials

and is skinned in black gelcoat. High

temperature

"iso" tooling resin is used wherever minimum

shrinkage is desirable.

The heat distortion temperature of our resin is 220 F -

(standard polyester

resin: 180 F, vinylester: 210 F. When you realize that the

engine

compartment temperature can reach 200 F plus, it becomes clear why we

chose

the resin we did.

We use random strand mat for all our panels to prevent cloth pattern print-through. |

| ||

|

|||

Structural DetailsFiberglass Reinforced Plastic is a wonderful medium for low volume production, but it does have a disadvantage: FRP has a poor memory. Pressure on it for an extended period of time will distort it slightly. While you may not be able to feel it, the distortion will be visible in a good paint job. E.R.A. has taken the stress off the outside body. In fact, we've never seen a stress crack in an ERA body, even after 18 years! The inner body panels are fastened to the chassis by bonding and riveting. This takes a bit more time but results in a solid, rattle free, semi-unitized structure. |

Click here for details on how we mount the body from the manual. Even with the body in place, removal of the engine and transmission is still very easy. The 289FIA is designed to be serviced like a real car. If you think being able to remove the body would be an advantage, consider all the things that would require disconnection or removal: Wiring, steering column, bumpers, windshield, etc.... |

| This

is a 427SC

body in our assembly jig - with

fiberglass inner panels. The

FIA

has

aluminum

panels attached to tubing

jig-bonded

onto the

hidden edges

of the body.

Print-through is prevented, and the fit and shape of the body

is

consistantly good. We gasket

the

areas between the aluminum inner panels and the outside body to seal

them.

This prevents any distortion of the visible body surfaces.

The light color that you see on the inside surface of the fender is Coremat. This is a low density material that allows us to add thickness without weight, preventing stones thrown from the tires from "spidering" the outside body. |

Trunk PanelsOur aluminum trunk panels are attached to the chassis and use weather-stripping to seal against the outside body. The spare tire well is fiberglass, just like the original cars. |

|

| Door ConstructionThe doors have a steel frame supporting the fiberglass inner and outer shells. The framework supports the heavy duty hinge and latch mechanisms, with the fiberglass shells remaining stress free. The doors are hinged and latched directly on the steel chassis, eliminating sagging and mis-alignment. OiliteTM bushings are used at the hinge pivot - there is no steel-to-steel contact.The hood and trunk lid are two piece: An outer skin and a finished inner panel carrying the hinges and latches. The original style hinges of the hood and trunk lids are attached to the inner panels only, with nut plates for attachments bonded in. And, everything is fully adjusted at the factory for proper alignment. |

| ||||

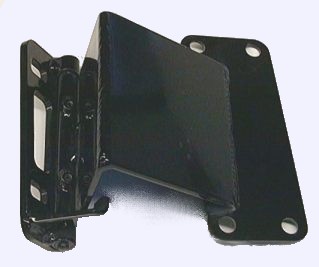

| Our hinge boxes place the pivot

point

of the hinge very close to the outside skin, but

not touching.

This gives maximum edge clearance when the trunk is opened or

closed.

We do the same thing with the doors.

The inner and outer panels of the hood, doors and trunk are bonded together with a special low-distortion epoxy and finished smooth at the factory for that professional look. |

| |||

| The hinge boxes are

bolted onto the fiberglass

inner panel.

Easy adjustment. No

stress on the outside body.

In

other words, our bodies will stay Good Design. Good Car. |

| |||