Flat-face clutch throwout bearing

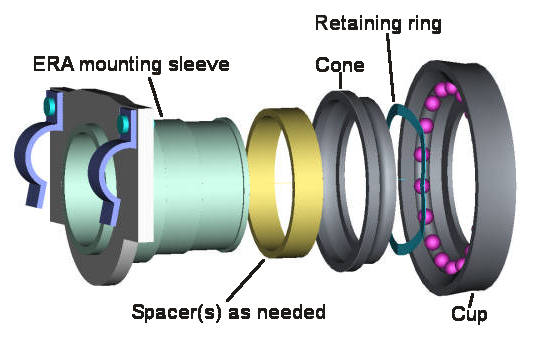

A flat-face Ford bearing is necessary for clutches with "bumpy" fingers. Start with a standard Ford small block bearing, Federal Mogul/Bower 614038. The ERA mounting sleeve is specially machined for the Ford bearing.Go here for machining instructions to modify the old-style ERA sleeve. Only the retaining ring groove is added. Everything else remains the same.

Note! Keep all bearing parts dirt free!

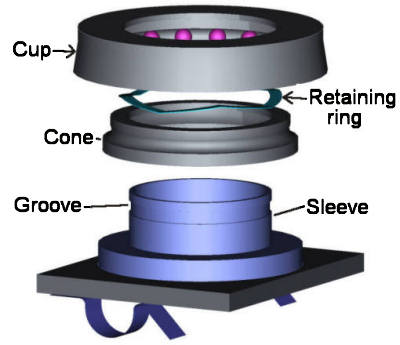

To Disassemble:

- Support the bottom edge of the cup with a suitable press adapter.

- Push onto the top edge of the sleeve so that the cup is separated from the bottom assembly.

- Remove the retaining ring from the sleeve, allowing the cone to come off the sleeve.

Stock Ford throwout bearing, exploded view

Figure out the bearing face height necessary as described in the manual. Note that the spacer fits into the step of the cone. For reference, the distance from the cup thrust surface and the cone step (where the spacer touches) is 0.23".

- Once the spacer thickness is determined, assemble the spacer(s) onto the sleeve, followed by the cone and the retaining ring.

- Press the cup onto the assemby. Make sure that the seal remains in place.

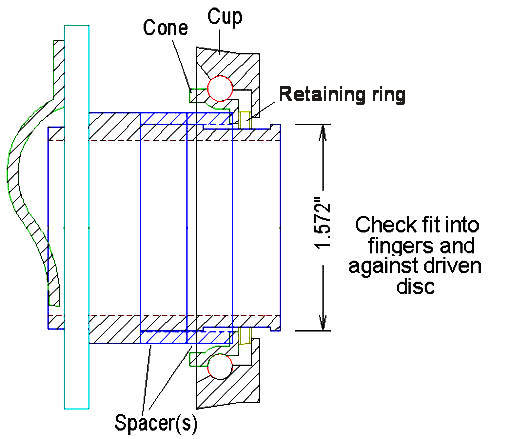

Ford pieces assembled onto ERA sleeve

Check that the sleeve clears the fingers and the driven disc. If necessary, the end of the sleeve can be trimmed off. The step at the end does not have any real function and it won't be missed. The retaining washer is a tight fit on the sleeve.

Note that the bearing actually floats a bit diametrically, probably making it self-centering.