Road and Track - December 1979SalonThe

man behind it all was Texan Carroll

Shelby.

who had a long and successful career as a race driver behind him and

had only quit because of a heart problem. Before his retirement. Shelby

had tried to interest General Motors in a competition sports car, hut

GM was interested only in Corvettes. so Shelby directed his immense

charm and powers of persuasion in Ford's direction, with considerable

success. What he actually did was to bring together Ford's engines (and

Ford's money) with AC Cars Ltd in England, the builders of the AC

Bristol. In the best tradition of the British

specialist car

builder, AC Cars is nothing much more than a fabricating shop in the

main street of a sleepy little English village called Thames Ditton. At

the time, the Bristol Aeroplane Company had just stopped production of

the engine used in the AC Bristol and Shelby felt that a small-block

Ford V-8 would be ideal. He caused a modified but engineless AC to be

flown to Los Angeles, where he and Dean Moon had it running within

eight hours. The Cobra was born and Carroll Shelby was on his way.

|

The true ancestry of

the Cobra goes hack as far as 1950, when a

relatively unknown designer named John Tojeiro decided to offer a

racing sports car chassis, which would accept almost any of the

available competition engines of the time. Working by himself, Tojeiro

built what was eventually to become the basic layout for the Cobra. One

of his first customers was named Cliff Davis. | Davis

ordered his car with a tuned version of the 6-cylinder Bristol engine.

When it came time to body the car, Tojeiro was in a hurry and also

somewhat lacking in resources, so he looked around to see what other

people were doing. Showing excellent taste, he settled on the beautiful

little barchetta body with which Carrozzeria Touring had clothed the

Ferrari 166 Mille Miglia. and built a fair copy of it. although he

simplified it along the way to suit the available amounts of time and

resources. The TojeiroBristol became a famous and successful car and.

thanks to Touring, it had an ageless appearance. At

the time, AC

-Cars was having some bodies built by a company called Buckland Body

Works Ltd, which was close to Tojeiro's shop, and Derek Hurlock. who is

now the boss of AC, heard about Tojeiro while on a visit to Buckland. A

deal was made and Tojeiro cooperated in adapting his design for road

use and the car appeared as an AC, first with AC's own 6-cylinder

engine and later with the Bristol. Because it was

built in a

fabricating shop. the AC Cobra benefited enormously from its extreme

simplicity. The chassis consisted of two 3.0-in. diameters steel tubes

connected by crossmembers in ladder-style with spring towers at each

end. Body framing and support brackets were welded to the main tubes

and the bodies were of aluminum. Front and rear suspension was by

transverse leaf springs and lower A-arms, and disc brakes were used all

around. In the early stages of production, a number of modifications

were made from time to time so that there was a certain amount of

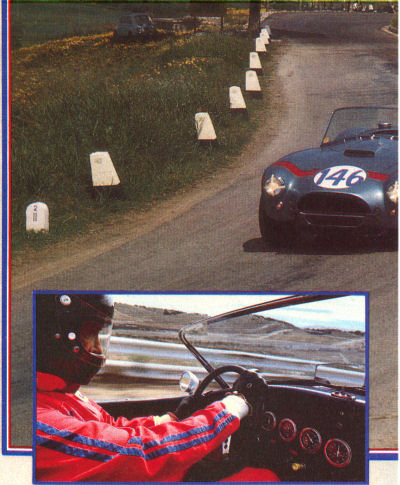

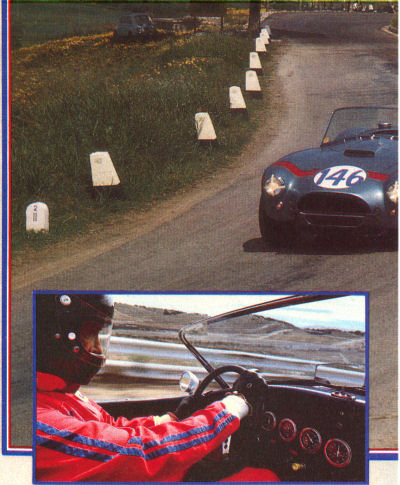

variation between the cars. The first contract was

for 100 cars,

which were delivered between December 1962 and April 1963, and the

first 75 of these were fitted with Ford's 260-cu-in. engine. However,

Ford starting to build a 289-cu-in. engine which was absolutely ideal

for Shelby's purpose. Ford had been doing extensive research into

methods of thin wall casting, so the new engine was light. It had a

rather extreme bore to stroke ratio of 4.00 in. to 2.87 in., which

also helped to reduce the weight as well as keep down the piston speed

and permit big valves to be used. and it was offered in a

high-performance version giving 271 bhp. It was one of the best engines

ever built.

|

| The

engine in Mike Shoen's car was, of course, tweaked by Shelby's men. but

not excessively so. Shelby's sworn intention was to win with a team of

Cobras the series of classic races which counted toward the

international manufacturer's championship. a' to put it more succinctly

in Carroll's words, "To git Ferrari's ass." These races included Le

Mans, the Targa Florio. Sebring and other long-distance events, so

stamina was just as important as speed. Fortunately, the engines were

extremely rugged just as they came out of the box, so the stock

crankshafts, rods and pistons were retained after being balanced.

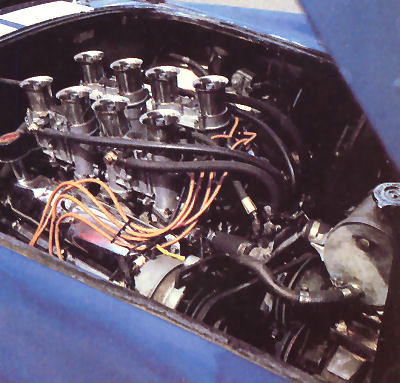

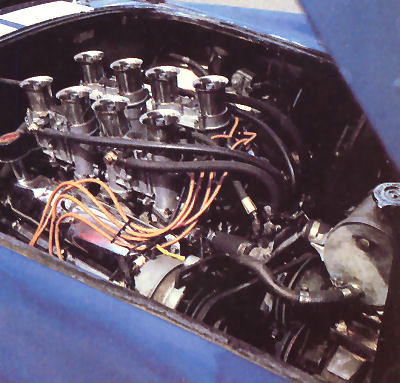

The

two engine men were Cecil Bowman and Jack Hoare and their primary job

was very careful hand assembly to fine limits, and considerable

attention to the gas flow through the heads. Four twin-choke, downdraft

Webers were used and the diameter of both the intake and exhaust valves

was increased by I /16 in. To take advantage of the larger valves, the

ports were opened up and finally the complete combustion chambers were

polished. Various compression ratios were used, but 11.6:1 was about

normal. With these and other modifications, such as different valve

overlap and ignition timing, the engine put out between 340 and 370

bhp. This output by no means stretched the engines anywhere near the

limit, and Phil Hill recalls them as being very reliable as were the

whole cars. Furthermore, according to Phil. the torque characteristics

of the engines were such that you didn't have to bother very much where

you were on the power curve.

|

|