289FIA

and Slabside |

|

||

| See

our Dedicated Information Pages at the right for specifications, parts lists and performance! It's really best to read all the F.A.Q.s, but if you're impatient, you can use our INDEX to jump directly to some special areas! |

|

Why a rectangular tube chassis |

|

You've just updated your 427. What's going to happen with the FIA?

| |

When I receive the standard kit, what will it look like? It looks like a car without the suspension and interior! The standard kit is shipped with the body (including doors, trunk and hood) pre-fit and mounted to the chassis. All the lights are installed, and the windshield is mounted. The foot-boxes, floors and interior bulkheads are fit. The fuel tank with filler pipe and cap are also installed. The suspension, wiring and interior are packed in boxes. | |

Can I buy the kit in stages? The frame first, and then the body?

Sorry, no. We custom fit each body to the chassis to insure that everything will line up correctly. Frankly, we are much better at this than you could be, and we want to keep the final quality high. Besides, too many people have an unrealistic view of how much the project will cost and would end up with a permanent dust catcher/bad investment in their garage. Not our style.

On the other hand, we are very flexible as to the composition of every kit. We will make every effort to give you exactly what you want, without compromise! We've posted some sample kits here so that you can get an idea of what combinations are fairly typical.

DESIGN

What's so special about the E.R.A. 289FIA and Slabside?

From the beginning, we designed the E.R.A. 289FIA to look exactly like the original car, but without many of the original Shelby 289's shortcomings. We have strengthened the chassis, improved the body mounting and material, and refined the suspension to make a better street car.

| "All three are good cars. The quality of the finished product is dependant (sic) on the builder." | (A quote from someone on ClubCobra.) |

With some kits, that may be the case. But - because an E.R.A. is so complete, and the engineering so thorough, it's pretty hard to build an inferior car. Use quality mechanical components, and the resale value of your finished kit will make you very happy.

I suppose you could do a poor paint job.

You don't use a donor car?

No. We felt that there would have been too many compromises to the basic design, performance and visual effect. While the potential to save money is there, there's also a whole bunch of dirty work involved in the process of disassembly, cleaning, and replacing used parts. It all adds up to extra time, work and unforeseen expenses.. And if you want to end up with something new, you'll have to rebuild or replace many of the components. Just ask the people at FFCobra Forum.

Why don't you use somebody else's front suspension?

There were no off-the-shelf suspensions that met our design criteria for both the front and rear suspension. Instead, we selected components that could be integrated the way we wanted them to. We were able to match the roll centers with the line of the front and rear center of gravity.

The alternatives we didn't like were:

-

Mustang II, etc. Lousy geometry, small brakes, solid rear axle (cheap though!)

-

Jaguar (front): Lousy geometry, small brakes, expensive, but pretty.

What about Corvette suspension?

Corvette ('84-on) suspension presents several problems:

-

Pin drive wheels cannot be easily accommodated with the late model's integral wheel bearings. Our ERA GT must replace the Corvette uprights and bearings with completely custom pieces. Can you say "expensive"?

-

In the front, using the Corvette control arms requires an extremely short steering gear. We could use an aftermarket unit like Appleton or Sweet, but these are not meant to go tens-of-thousands of miles, and their straight cut gears allow too much feedback for the street. In addition, the standard Corvette brakes won't fit into 15" wheels, which proscribes the use of reproduction pin-drives.

In the back, the Corvette track is much too wide. The half-shafts and lower control arms have to be changed. That's no big deal, but...the cast aluminum differential cover, which also acts as the mounting bracket for the entire assembly, would have to be extensively modified or replaced too. There is also a strength issue with the differential. Only the LT-1 differential would be as strong as the Jag. It uses the Dana 44 gear set too.

-

There is also a problem fitting the later 12" brakes into 15" pin-drive wheels. They don't. On our GT, we use only 11.5" rotors on our custom hubs. Since you can't easily modify the hubs to move the caliper in, you're stuck with the earlier, smaller brake calipers that were used only a couple of years.

-

Thought you could get away using the stock shock and spring? Sorry! The leaf spring is too long. We could either make a new spring - an interesting proposition - or go to coil-overs. This requires making a new shock bracket on the hub carrier. More complication.

Why

is the

rear

suspension in a subframe?

Why

is the

rear

suspension in a subframe?

Using a subframe is unique to E.R.A. The subframe isolates the differential noise and vibration from the chassis. It also lets us use trailing arms to locate the lower control arms as originally designed. Without trailing arms, the lower control arms are put into bending modes that they were never designed for, allowing excessive toe change with power and braking forces. Contemporary Classics' (Now Burtis Motorcars) replica has an optional Watts link system that partially compensates for this - for about $1500! Our subframe also makes it easier to service the assembly. The rear suspension can be built as a unit outside the car for convenience, and installed into the chassis in less than an hour.

Is the Jag differential strong enough?

You bet! The Jaguar piece is a Salisbury made unit that uses Dana 44 gears. It was used (with a slightly different casting) in the original Shelby 427 Cobra. The few problems some people have encountered resulted from drag strip events while using high-traction slicks - and roughly 600 bhp. -And that particular weakness can be cured with available high-strength stub axle shafts from us or Concours West. Remember! You can only exert so much traction in a car that weighs 2400 lbs., even with over 50% of the weight on the rear axle.

What about the rest of the pieces? I've heard that the Jag axles break.

You use the half-shaft as the upper control arm?

Yes. Because the axle is much stronger than any control arm could be, and we modify it (see above link) to be fail-safe, there's no reason not to use it as a working member. The axle has proven to be absolutely reliable in more than 800 cars.

That dual-use saves weight, space and complication.

Can't I use a solid rear axle?

The chassis is not designed for a solid axle. Because of the engine placement, the drive-shaft would end up too short for adequate wheel travel. Some other kits limit the travel to 2" total! We have 6.5"! If you drive on less-than-perfect roads you will appreciate the "luxury" of an IRS. A good independent suspension (like ours, of course) will give you excellent handling with a reasonable ride. The original Cobra had independent rear suspension - for a good reason!.

How about the Ford 9" differential?

There are several reasons that the 9" isn't the best choice: The unit is not interchangeable with the Salisbury in our subframe and would require aftermarket calipers and a very Rube Goldberg emergency brake. Also, the pinion offset is about 1.5" lower than the Salisbury, making the driveshaft angle down excessively. Since it wasn't designed for an IRS, the conversions are quite expensive too. Since strength is not a factor (see above), it's just money down the drain.

Why

do you have an optional rear

suspension?

Why

do you have an optional rear

suspension?

Many of our customers spend most of their time on the track. While the Jag brakes are perfectly adequate for hard street use, they don't cool well under track conditions. We took the time to re-design the whole assembly to move the brakes outboard and make them bigger. We also changed the geometry a bit for more stable high speed cornering at the expense of tire wear.

Note that as of 9/2010 the ERA outboard-braked rear suspension is not available on the Slabside. We are working on a different design using all Jaguar XJS components.

What about all-wheel-drive?

That's just too many mechanical parts to fit into a small car with a big engine!

Can I get a roller?

Sure! We don't have a standard package because of all the possibilities, but we can put together exactly what you are looking for. The roller will have all the parts installed and functional: Typical cost is approximately $5000 plus the cost of your wheels, but the individual prices are listed here.

- Front suspension, with adjustable coil-over dampers

Optional anti-sway bar- Front brakes, complete and functional - Standard GM or

optional forged Wilwood calipers on 11" or 12.2" vented rotors- New steering gear

- ERA custom steering column and Moto Lita wheel

- Rear suspension - either Jag-based or our own ERA-design

Optional anti-sway bar- Brake reservoir

How do you make the fiberglass body?

The main body, doors, trunk lid, hood and the inner panels are all hand-laid right here at our production facility. We use a high-temperature low-shrink resin and the best quality fiberglass mat. We don't use cloth because it will eventually print throug the gel coat and ruin the exterior paint's finish.

After the main shell is laid, it is rough trimmed. Then it goes to the assembly shop where it is put in a jig where the inner panels are bonded and holes for the lights are cut. Then, each body is hand-fit to its chassis so that you know that the doors, hood and trunk will function perfectly when you pick up your kit.

Do you offer an aluminum body?

Sorry, no. While we use aluminum panels for most of the inner panels, we don't have an aluminum body skin. For that, go to Kirkham Motorsports or Shelby American. It is not practical to retrofit an aluminum skin to our chassis because of our unique method of using bonded inner panels as an intermediate support structure for the outside skin.

Does your kit use a "tubbed" interior?

No! Except for the fiberglass footboxes (as used on the original car), the interior is built up of separate aluminum panels riveted and bonded to the chassis and to special flanges bonded to the door openings.

In addition, the wheelhouse panels are all CNC-cut alumninum, protected on the visible side with plastic sheet so that they stay scratch-free during construction. We use 0.050" thick Marine-grade (5052H32) aluminum throughout for the best resistance to staining and corrosion. You can see what happens to non-mariine grade (6061) aluminum under adverse conditions here.

Why do you bond the body to the chassis?

The results are a stiffer overall structure, with no rattles, creaks or shakes. Our fiberglass bodies do not get stress cracks, even after many hard miles on the road. It is a bit more work, but well worth it! Some claim that their body is "unstressed" because it is rubber mounted to the chassis . Wrong! The outside shell must still be supported with inner panels or some other structure. The method of that connection is what determines whether stress cracks will appear. Furthermore, with few supports, the body will move relative to the chassis when the car goes over bumps. That's what is typically known as "cowl shake".

Doesn't bonding the body to the chassis make it more difficult to work on?

Not really. Our car, with its removable tunnel, is designed to be very easy to service. In fact, every turnkey we do at the factory is painted before any of the mechanical bits are installed.

What about stone chips from stones thrown up by the tires?

All our bodies have thickness added to the fiberglass (with Coremat© and an extra layer of glass) over the tires. Many people also add vinyl protection or spray-on Chip Guard© on the front of the rear fenders to fend off stones thown from the front tires.

Why do you use separate aluminum floor and bulkhead panels in the cockpit?

We have tried to duplicate the construction of a "real" car as much as possible, and avoid the dune buggy syndrome of a single interior shell. This is a bit more work to put together, but saves weight and allows much more design flexibility. Our aluminum tunnel is removable for service, and we have an access panel behind the seats for rear brake service. Separate footboxes also allow us to create a stronger structure to support the cowl and door mounting hinges.

How much does your car weigh?

The 289FIA weighs about 2350 lbs with an iron 302 Ford engine and T-5. This is about 100 lbs more than an original car, put mostly into the stronger chassis. Some other kits claim much lower weights. What they don't tell you is the strength of their car is much lower, and they are missing a lot of pieces necessary for an authentic street car. Weight distribution is 50F/50R with the heavier engine combinations, moving up to 47F/53R as you "add" aluminum (driver not included). The ERA rear suspension will reduce the weight (off the rear) by about 50 lbs.

When you feel how solid our car is, you won't regret the slight extra weight! Factory Five has a car that allegedly weighs 1800 lbs, with carbon fiber body and aluminum engine. The trouble is, it's a race car. You can't drive it on the street!

DRIVE-TRAIN

What engine do you recommend?

The 289FIA is designed around the Windsor 289/302/351. The Boss 302 and 351 Cleveland will fit too, but the exhaust will have to be custom fabricated. We also have engine mounts for small-block Chevrolet but remember, all E.R.A.'s are famous for having the "correct" mechanical parts. If the time should come where you want to sell your car, an odd engine will probably make your car worth a lot less. A good reference book is Ford Performance by Pat Ganahl, available from Amazon.com and Barnes and Noble on-line book stores. Just search on the authors' names.

What about the Ford Mustang 4.6L "Modular" (32 valve) engine?

We have installed one of these engines into an FIA chassis. It was a difficult and expensive project, requiring new reduced-width footboxes, modified steering column and pedals.

The oil-to-water intercooler must be removed from the block and a custom block-off plate made. New fuel feed and return lines must be made, and a very expensive wiring harness is required. Sorry, but we cannot recommend this engine.

What about a Chevy?

Noooooo!

Seriously, we do have mounts for the Chevy, but we strongly discourage it. We have only done a few 427SCs and no FIAs with them, and a couple of those have been converted back! We have done no detail development work with the "mouse" or "rat" engines except for the mounting system. You will have to adapt the wiring harness, and make custom headers and clutch release system. The Chevy engines, in addition, are significantly heavier than their Ford counterparts. In our experience, when you sell the car, it will be valued almost as if it had no engine at all.

How do I find an engine builder?

You can use someone locally or we have our own list of preferred builders that you will work with directly.

What's the best transmission to use? With all Ford engines, you can use the original Top-loader 4 speed (built by Dan Williams or David Kee) or the Richmond Gear 5 speed. The 4 speed is normally combined with a 3.54:1 or 3.31:1 differential ratio, depending upon engine size and tune. The 5 speed has a direct drive 5th and works best with a 2.88:1 or 3.07:1 ratio for a better top gear cruising RPM. A Tremec TKO, TKO II, 500 or 600 5 speed can be used with all engines, using a 3.31 or 3.54:1 differential. We do not support the Richmond Gear 6 speed or late-model Ford T56 (modular-engined) transmission. |  |

Certain variations on the T-5 (as described here) can be used with engines up to 450 bhp.

The "best" transmission for you depends on what you're going to do with the car. For everyday driving, the Top-loader wide-ratio or Tremec are the best choices. Both offer a good starting gear, and the Tremec has an overdrive 5th gear for comfortable highway cruising. The close-ratio Top-loader and Richmond Gear 5 speed are more performance oriented, with gear spacing that keeps the engine's rpm's within a narrower range. Specific gear ratios are listed in our downloadable assembly manual.

While we haven't done many, you may also specify chassis mounts for a C-4 or C-6 automatic. We will eliminate the clutch pedal and move the brake pedal to the left on request.

What about the shift handle and linkage?

The shift handle was straight up in the 289, with a reverse lockout built into the lever. E.R.A. offers a reproduction handle and linkage for both the Top-Loader and the Richmond Gear 5 speed, and also handles that bolt onto the Tremec and T-5. The "T" handle is still there for visual accuracy, but is non-functional.

What kind of clutch should I use?

Because the car is very light, a standard-pressure clutch is fine. Any slip will come (accidentally, of course) from the tires.

What are pin-drive wheels?

The original Shelby Cobra wheels used a single wing nut that secured each cast magnesium wheel. The power was transferred from the hub to the wheel by six pins. The 289FIAs used a casting unique to the race cars. PS Engineering is now duplicating the original design in aluminum, with offsets that fit the E.R.A. cars. For day-to-day use on the street, magnesium corrodes quickly and requires too much maintenance.

If you want 17" pin-drive wheels, they are available from Dr. Dix and PS Engineering.

What are the other wheel alternatives?

American Racing's Torque-Thrust wheels look great and actually are similar to the bolt-on Halibrand that was used on an original drag car. Halibrand is also still making the wheel - even in 16" rim diameter, although only 8" wide! Recommended specifications are available here. Team III and Vintage Wheels make a 427-style wheel thats available in 15 and 17" diameters in the appropriate offsets too.

How

about a spare tire?

What kind of brakes do you use?

|

What about the exhaust system? We offer both a comp-style (at right) and under-car exhaust pipes in many variations. The under-car system shown at the lower right duplicates the look of the original street car and is quiet under cruising conditions. Ground clearance is about 4" under the tri-flow mufflers. The twin tail pipes exit at the rear of the car next to the bumpers or jackpads. You'll lose a bit of horsepower compared with the "comp" exhaust, though. The undercar exhaust is also incompatible with the ERA-designed rear suspension unless a narrower wheel is used. |

|

Is my car going to overheat?

|  |

Where's the battery?

|

|

PERFORMANCE

How does the car go?

Depending on the engine, 0-60 MPH times will be from 4 to 6 seconds.

How does it stop?

Very well, thanks. Stopping distance from 60 MPH is about 145 ft. The brake balance is adjustable for personal tuning. A car with stock brakes did 0-100mph-0 in 12.07 seconds. You do the math!

Standard brakes consist of 11" vented rotors in the front, 10.5" solid rotors in the rear. 12.2" rotors with Wilwood calipers are optional for the front. Our optional rear suspension (only available on the FIA) has outboard rotors, 11.5"OD x .81" thick standard.

Like many of the original 60s sports cars, we don't use a booster in the system. The pedal pressure is moderate but very positive.

How does the car ride?

Surprisingly well. Spring rates, while not exactly boulevard cruisers, are quite reasonable for such a high performance car. The fact that chassis flex is so low enhances the feeling of total control.

The new owner commenting on a 427 kit #490 (built 8 years ago):

"I wish my Acura was this solid."

And another comment on Club Cobra

The suspension is so supple that the ride is comfortable even with 17" wheels.

How does the FIA/Slabside compare to a modern sports car?

You're more in direct communication with the road. Without power steering, you feel much more - and it takes more effort to do things. "Bite-wise", the car will stack up quite well to its equivalent new car. Fitted with new rubber, the FIA will do over .95G with street suspension. And it doesn't bounce from bump to bump - there's plenty of suspension travel. This is a car bred for Connecticut, where potholes are the companions.to our favorite back roads.

From a post on Club Cobra, 5/2011

Thanks, guys!

The maiden voyage was fantastic. The engine note alone is entirely worth it; I think that is the main reason I wanted a Cobra in the first place!

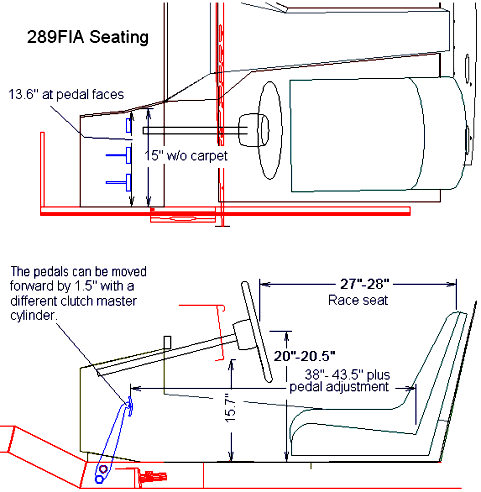

Absolutely delighted with the driving. Rock solid tracking, and the suspension handles all the bumps we have up north flawlessly. Steering, brakes, pedal placement, driving position, all just right.

Webers were nearly perfect. I tried but couldn't really find the transition from the idle to the main circuits, smooth all the way up. I could cruise at and smoothly accelerate from any RPM. No need to try to keep it in the main circuit RPMs (around 3,000 and above). Perfectly behaved in street traffic and a beast when let loose. And the sound as it winds up! I could listen to that all day!

Some who have the dual outlet Weber manifold and the oil cooler complain about not maintaining enough engine heat on the highway. I did not have that problem. Heat stayed right at about 140 degrees, sometimes a little under.

Although they weren't supposed to, the fancy McTrumpet stacks and wire mesh screens disrupt the air flow enough that Doug felt the Webers lost a little something at the high end. After Carlisle, I'll take it to Inglese for a look. May just go back to the open stacks.

Didn't really come close to the limit cornering, braking or accelerating, but it feels easily as strong or stronger on all counts than the Porsche Cayman, 911 and BMW M3 I drove at a Skip Barber school at Lime Rock (M3 is the closest). I don't think the Lotus Exige (which I also drove there) would have much edge handling, and it is a lot less comfortable than an ERA. And the Lotus doesn't make that great sound!

In fact, my ears are still a little sore after three hours driving yesterday. The noise is not really bothersome while driving, but I guess it adds up over time.

As far as wind goes, the car is pretty comfortable around 60-65, so the temptation to speed is dampened somewhat (almost got caught nonetheless!). Around 80, I wouldn't trust keeping a baseball cap on for very long.

The Kirkey is VERY comfortable even though it initially feels snug. Very happy with that choice. I'm 6', so sitting on the floor isn't a problem with visibility.

To anyone starting a build, I very much recommend the rectangular rear view mirror for the cockpit: you can hardly see anything in a Raydot.

The combination of the 3.07 differential and the Richmond Road Race 5-speed is very good. The 3.04 first is just right: starts rolling easily but I still get a nice long pull. The 1:1 final probably isn't the best for cruising and highway gas mileage, though, but I knew that going in.

The instruments all look great, but the NOS speedo started to go haywire after about 15 miles, so that will need attention at some point. I also think it is undercounting mileage. The only thing I would change is the placement of the oil pressure gauge. Where it is now it is partially blocked from view by the steering wheel. I think I'll have it swap places with the less critical fuel pressure gauge so it is easier to keep an eye on.

The only thing on the drive that was a concern was, more often than not, I got a bit of grinding on the shift from fourth to fifth. Very strange; no idea why that is happening. I'll check in with Doug and Peter tomorrow.

BTW, the 289 is now the hot car at ERA: Peter P. said that his backlog is nearly all slabsides and FIAs, with a couple of GT-40s. No 427s other than what's in the shop.

So there you have it! I'm officially an ERA owner now! Time to go for a drive!

How about fuel economy and reliability?

You have to ask??? Seriously, the more "stock" the engine is, the better the mpg. You could get 16-20 mpg out of a low horsepower 289 or 302, but with 500 bhp, you'll probably get 10 mpg. If you want the best reliability, stick with a stock engine. Unless you throw a lot of money at an engine, higher horsepower will always result in higher maintenance.

| How about this for a quote? | "Bob,

thanks for the info on car 191. The current owner has done some improvements to the engine and ignition. He loves the ride and says his friend who owns big block Corvettes says your ERA rides 10 times better! He even said it rides as well as his 85 5.0 Mustang!" |

| Because we've spent many years "standardizing" springs and dampers, you can be assured that you can have the same high level of comfort. | |

Do you have any interior ventilation?

We have footbox vents on both the drivers and passenger's side, controlled by separate dash knobs and fed by scoops in front of the radiator. Few other kits even offer ventilation. Air conditioning, however, won't fit - and would be ineffective if it did.

Can I drive it in the winter?

One person's experience: |

"Bob, I saw your response to the fellow who wants to know how to drive in the winter and with what equipment. As you know I am going into my 3d winter of driving my 289. The top is on and the sidecurtains go in if it is particularly cold or inclement. I rarely use the heater/defroster, because the cockpit with the heat vent on is plenty warm. I have driven in snow, rain, and the dark of night. The Cobra keeps on trucking. Tell the fellow to JUST DO IT!" |

What's

the difference

between your standard vinyl (street-style) seat

and the optional leather ones?

| Not a lot! |

|

|

Is it possible to fit air conditioning?

Yes, with some limitations. A small compressor will fit on the engine OK, and there is enough room for a condenser on the radiator. So far, the only thing we've found that will fit under the dashboard is a smallish 8000 BTU evaporator unit. Anything larger may have to be custom made, adding to the cost. However, our knowledge of A.C. is limited. A professional AC shop might know of better systems available. As a compromise, we can design brackets for the compressor and condenser and you can go to a local shop for the rest. The system will also require our optional heavy duty fan.

I'm LARGE. Will I fit in your car?

|

| |

| ||

How comfortable is the passenger with the roll bar brace right there?

|  |

Do you have a convertible top?

Of course! The optional top is a duplicate of the original, fastening to the windshield and the lift-a-dot fasteners on the rear cowl. It uses a removable bow for support over the driver.When not in use, the whole thing can be folded and stored in the trunk. Side curtains are also available.

Can a put a radio in?

Yes, either on the tunnel or hidden in the (street dash) glovebox.

CHOICES

Why do you offer comp, Drop and 427-Street dashboards?

The original street 289 had the speedometer and tachometer flanking the steering column, with the balance of the gages in the center of the dash. They also had a glovebox on the right. The FIA race cars had the speedometer mounted toward the right side of the dash, and it didn't have a glove box. E.R.A. offers both layouts.

I've seen cars with different types of hoods. Which do you have?

The ERA 289FIA is available with and without a molded-on hood scoop. The original street 289's didn't have a scoop, but the comp cars did. The scoop is necessary with a 351 engine. Some 302's will fit under a plain hood.

Do you offer Right Hand Drive?

We don't have off-the shelf pieces to make an economical switch. It's fairly easy to switch the steering and brakes, but the foot boxes will have to be custom made. Figure in the thousand$.

Why do your fender flares look different from some of the kits I've seen?

To be blunt - Because theirs are wrong! We took great pains to copy the only original FIA body left. All the other cars have been rebodied at one time or another. After all, all the FIAs were race cars and were involved in occasional shunts.

Do you offer a "slab sided" body like the original street 289?

Coming soon!. Our prototype is complete, but besides the body changes, we had to re-design the chassis to accommodate some suspension changes. We expect production will start in the spring of 2010.

If you don't want to wait, you can make a reasonable facsimile of a street car (built by AC) sans "slab sides" with wire wheels, front grill, no hood scoop, street dash, without the trunk bumps

Can I get the chassis powder coated?

Yes. A special chemical and impact resistant coating is baked on. Very durable, and looks good too.

CONSTRUCTING THE KIT

What do I have to fabricate?

Every basic bit that you can't buy off-the-shelf is included in the kit. You don't have to make anything.

Do you include the nuts and bolts?

Almost every fastener is included in the kit, unless it is specific to installing your particular drivetrain. We use stainless steel screws in non-critical but corrosion-prone places like for the hood and trunk hinges. Pems (or other systems captive threaded nuts) are used extensively so that no place requires two people to install a component.

The suspension pieces are all Grade 5 or Grade 8 where appropriate.

What is the most difficult part of building the kit?

Probably building the rear suspension assembly. It entails lots of shimmed bearing packs, seals and caliper/emergency brake rebuilding. Even with the experience of doing hundreds of assemblies, we still spend about 15 hours on each one.

If you still want to do it, we can help a bit with parts and advice, but you should still get a good manual. Alternately, you can purchase an assembly from us or Concours West, a Jaguar rear-end specialist.

Birth of a New Machine - Dan Somers' story of building an ERA kiit.

Do you have a "turnkey minus" package?

We don't have standard "packages", but because we are so flexible, we can build exactly what you want in a kit. If you "back out" of the turnkey specifications by subtracting roughly $9000 for the standard engine and transmission, you can get a good idea of the costs involved. Alternately, if you are willing to do just a little more construction, look at some of the sample kits listed.

Speaking of manuals, what's yours like?

Thanks,

Jon

Yep, me too - when I built my Unique.

PhilAbout 140 pages of detail, including exactly what you need, how to prepare the used stuff, and how to assemble it all on the kit. Lots of illustrations. I used some of them in the web illustrations, and I have a link that showed 2 typical pages from the manual. The text part of the manual is also posted on the web in PDF format and some sample pages are available here. A complete manual is also available in hardcopy, on CD or download (PDF) here.

The wiring instructions come separately - another 20 pages, so you don't have to drag the whole book around when wiring the car. Almost all connections are illustrated and every single connection is annotated with the wire's origin and purpose so that in the event of a problem, you can troubleshoot quickly.

I've never done any wiring! I know nothing about electricity!

You don't have to be an expert to wire the car. Our wiring instructions have lots of pictures and every connection is explained. All wires are terminated with soldered and insulate connections, color coded and labeled. The front and dash harness are modular units and connected together through multi-pin plugs. So - you can wire the dashboard while it's outside the car, minimizing the amount of time lying on your back underneath the dash.

What if I don't want to do some of the kit building stuff?

We will do anything you want to help you complete your kit. Each one is assembled to your specifications. We can also custom-make parts (within reason) if thatis what your kit requires.

Do I have to buy the trim and hardware?

All hardware, with the exception of the blind rivets, comes with the kit. This includes the nuts, bolts, grommets, clamps and screws. And most of it is already installed on the kit. Some of the badges are optional.

What if I can't find a part?

E.R.A. Stocks just about everything you will need to finish your kit. Some people have us supply every single part to complete the car.

Do you sell parts to the retail aftermarket?

Not currently. We only service ERA cars and customers' needs. Here are several companies that do:

Ken's Specialty Auto (315-793-0639

Finish Line (888-436-9113 or 954-436-9101 - FL and Int'l)

Cobra Restorers (770-427-0070)

Brooklands (305-776-2748)

Nisonger (914-381-1952)

Shell Valley (800-356-9198)

Operations Plus

Does your body need painting?

Yes. Some companies sell their car in "finished" gel-coat, claiming they don't require paint. But gel-coat will never look as good as paint, and you have fewer color and finish choices. Repair is much more difficult, also.

How difficult is it to paint the car?

|  |

Can I install the mechanical bits in a bare chassis without the body installed?

Yes, but we don't recommend it. With our turn-keys, we usually mount the body on the chassis first, then have the car painted. Finally, we install the drivetrain. The engine, transmission and suspension install easily with the body already in place.

What paperwork is included with the kit?

Each kit comes with a Certificate of Origin (also known as a MSO). This carries the date of delivery, not 1965.

SHIPPING

How is

the car shipped?

How much will it cost?

How is

the car shipped?

How much will it cost?

If you are within 500 miles and have a tow vehicle, consider picking the kit up yourself with a flatbed trailer or rental truck. We don't charge any extra for loading your car into your own trailer or onto any shipper that you've chosen. Just bring your own tie-downs.

For major distances, we typically use Intercity Lines, Horseless Carriage, Sunday Transport or Roadshow. They ship inside a box trailer all over the country. The price depends on your location. To major cities on the west coast, the cost would be about $3000. Trips to Florida run about $1500. If you are off the major routes, it may cost a bit more. Other shippers may cost less, but your car might sit in a depot for a bit, waiting for a direct ride. Most shipping companies have a $500 minimum charge. For short runs, we may be able to arrange transportation on a flatbed truck for about $1.50/mile.

For overseas shipping, there are several companies that specialize in transporting cars. SeaExpo is one that we've seen recommended on the public forums, but we have no personal experience with them. Shipping in a container is highly recommended for security.

I'm from outside the U.S. Can I get one of your cars?

ERA does not use dealers in the USA or Europe, so all your dealings will be directly with us. The difficulty varies from country to country. Sometimes there's a stiff tarriff.

Many countries have strict "performance" and design standards for complete or composite cars. ERA has not done any testing for compliance for any country, and you should assume that we will NOT meet their new-car standards or their special requirements for composite vehicles (kits).

It has been suggested that, since some U.S. states title their kits as 1966 vehicles, it might be possible to import a used ERA from such a state into their country. You do so at your own risk! Such an action goes contrary to the spirit of the law (and you might be subject to post-import penalties).

Most countries (most notably Canada) will accept "parts" from outside. We have, on occasion, split up a kit into separate shipments to make it easier for importing.

WHEN THE CAR IS DONE...

How do I inspect and register my car?

There's no such thing as "50-State-Legal system. Registration requirements varies from state to state. Most states will define your kit as a Composite or Home-built, some will call it the year that it's registered, some call it the year of car that it represents: 1965-1967. Because the cars have a special registration designation, no state requires you to meet current safety regulations although many will have a safety inspection to check on the basic construction. Contact your state Motor Vehicle Department for details and, if you have to go through an inspection, show up completely compliant! The link below will direct you to individual states' sites.

California cars, if they don't have a pre-1964 engine, must be registered under the SB100 system.

Connecticut, one of the more difficult, requires that the car be trailered to a central inspection station. There, they check the lights, brakes and general construction of the vehicle, and also make sure that none of your components are stolen. Keep your receipts!

For more details on inspection and registration, click here!

Do I get a title from ERA?

No. We give you a Manufacturer's Certificate of Origin (also known as an MSO) for the kit, plus a Bill of Sale. When you register the car, the state will issue you a title and registration number based on those documents (and the invoices from your major parts).. Most states will also collect appropriate taxes at that time too.

What about emissions?

Emissions standards also vary from state to state, and even regions within states. Most states will require that your car meet the specifications for the year of your engine. Another reason to stick with an early engine. It is usually possible to title the car as a pre-emissions vehicle as described in our REGISTRATION faq above.

What happens if I damage the car?

E.R.A. will sell you any repair part you need to fix it: Fender, hood, or even a complete body if necessary. We also can make pieces of the chassis and the proper dimensions for repair.

How difficult is it to maintain the car?

Remember how easy it was to work on cars made in the '60s? Welcome to the past! In spite of the size of the engine, there's plenty of room to do normal maintenance like spark-plug or oil changes. And if you want to get "modern", you can add electronic ignition too.

The front suspension uses very common GM replacement parts and service techniques. The rear suspension uses common Jaguar parts. All roller bearings and seals sare standard sizes, available at automotive and bearing supply houses. Part numbers for all replaceable parts are listed in the Assembly/Service manual. There are many suppliers specializing in Ford engines and various transmissions.

What about insurance?

It's surprisingly easy. In some cases a "Composite vehicle" can be insured by adding it to your current insurance. There are also some companies that specialize in this kind of car, like Lundberg Insurance (an ERA owner!), Heacock or Midwest Classic. The cost is pretty reasonable, with only some mileage restrictions. More popular companies are listed here.

Can I race my car?

|

| ||

| We

offer extra-large front and rear

brakes and an optional

rear

suspension for track use.

Our optional coil-over dampers

are externally adjustable for height and damping, making at-the-track

changes

very easy. The Performance Drivers Assocication and Sports Car Driver's Association also run events for their members. Click here to link to some video done at Pocono Raceway by the Performance Driver's Association. Look for the light blue ERA FIA shown above in the "in store for you" video. We've done quite well in the Northeast Replica Challenge too! We've posted the results for 2000 and 2001 |

How do you support your products?

We don't have a written warrantee, but we will replace anything defective within a reasonable period. After all, the amount of time that people take to complete their kits varies immensely. We have replaced pieces that were 5 years old.

If you insist on something written, you can write your own! We will agree to anything reasonable.

PAYMENTS AND DELIVERY

Why is your kit more expensive than most of the others?

The E.R.A. 289FIA kits come only in what others call a "Deluxe Stage". We don't offer a cheapo version of our cars. Frankly, we value our reputation too much to allow some people to butcher the concept and then claim that theirs is "an E.R.A." . We have included so much in our kit that, when completed, they all have the same high quality of design and materials. This fact is evident in the strong demand (and high prices) for our used cars. This car may actually be one of the most economical cars you've ever driven!

Just how much is kit this going to cost me?

Check out some sample kits!

How can I get a quote?

Please call Peter at 860-224-0253. Sorry, but you can't get a quote over the internet.

What about backorders?

E.R.A. seldom delivers a kit with anything serious missing. Backorders are usually shipped within weeks, and no one has had their completion date moved back because of missing parts.

How do I get the process started?

We require a $6000 deposit to get you in line for a kit or complete car. Once we get your deposit, the kit price is locked in - even if you defer delivery for 6 months.

What about the rest of the payments.

You must send another $5000 when we actually begin production of your kit. If we are finishing your kit, timely payments to the engine builder and painter will keep everything on schedule. Some extra payments for special parts may be required during custom construction.

Other taxes - sales and registration taxes - are typically paid when you register your car. For Connecticut residents, we collect the sales tax when you pick up your kit. You will not be double taxed.

When the kit or turn-key is delivered (or picked up), the balance must be paid in cash or with a certified check unless previously arranged.

What if I want to cancel the kit after I've given you a deposit?

The deposit is 100% refundable up until the time we actually start building your kit.

Can the details of my order be changed after the deposit?

Anything can be changed up until the time we actually start your kit. After that, we're still flexible, but there are limitations!

Is financing available?

E.R.A. doesn't finance, but for a turn-key car there are companies that specialize. Look at the CobraCountry web site for possibilities, or in the back of Kit Car or Kit Car Illustrated. Companies that have solicited us (but we cannot vouch for) are Gettysburg Financial, 954-786-2642, CreditCorp USA, (954) 771-2440, or JJ Best. Kits are more difficult to fund. You will have to use some other personal or business asset as collateral for a bank or personal loan.

How long will it take for me to get a kit?

Actual production time for a basic kit is about 2 weeks, but there is usually a waiting list, typically varying from 3 to 6 months. Occasionally, we might have an available spot in the queue from a cancellation, but that is unusual.

The current queue for a 289FIA kit is approximately 18 months.

For a turnkey: 24 months.

Is there any way I can get "immediate" delivery?

Bakker Ventures sometimes stocks kits that are available now.

What if I want my car even later than your waiting time?

Your deposit will hold your car for up to 2 years at the original kit price estimate.

Are there any unfinished kits available?

Rarely. Although some people sit on their kits for some time because of personal reasons, almost all are completed by the first owner. As an act of desperation, check the ads in Kit Car and Kit Car Illustrated.

What about used cars?

We generally don't deal in used cars unless it's a rare trade-in. Hemmings, CobraCountry.com, Club Cobra, the For Sale section of the ERA Registry site, and Dayan's House of Cobras frequently have ERA's, though, but don't expect any bargains. Resale value on ERA's is usually very high. The good part of that equation is that if you ever want to sell your car, you can get top money - without waiting forever.

What is the time frame for a turn-key car?

Add about 8-10 weeks over the kit schedule for painting, wiring, and mechanical parts installation.

Can I get names of people who have built your kits?

Of course. We can frequently find someone right in your area so that you can look at the "real thing" locally. Most owners are willing to talk at length about their experience. Some don't like to be bothered, though, so you must get names from our General Manager, Peter Portante (860-224-0253 9am-1pm, 3pm-5pm EST) at E.R.A. Sorry, but you cannot get references through e-mail.

You can also get independent information at the independent site E.R.A. Owners Registry

Other Interesting Facts

How many kits have you made?

We have shipped about 800 cars to date. Our current production is about 40 427s and 15 289FIAs. We also do about 6 E.R.A. GT's each year.

How big is E.R.A.?

We have a total of 15 full time people working in 4 buildings at our central location. We also have a separate R&D facility down the street. We do almost everything in house: chassis, body, small parts, rebuilding of rear suspension, upholstery, wiring harnesses and turnkey cars. We sublet the casting and machining, and most of our sheet metal is done locally at Fabtron, Inc. on a CNC punch machine. The owner of Fabtron has both a 427SC and an ERA GT! He knows about the quality we build into every car.

What other things do you do?

Most of our energy is devoted to the kits, but we do supply some small reproduction parts to the rest of the kit car industry.

It stands for Fédération Internationale de l'Automobile. It is the sanctioning body that makes the rules for international racing. The Cobra 289 in its FIA form was built to meet those specifications.

How we do things at E.R.A.

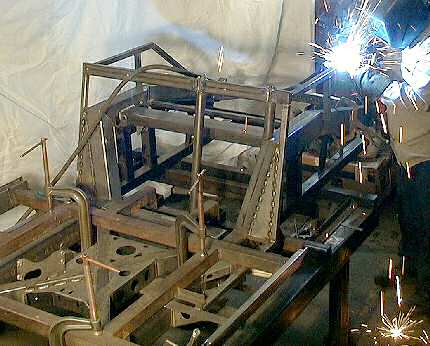

Where are the chassis' made?

|  |

And the suspension?

Suspension components are done the same way. Arms are cut and jig welded right here. The GT arms are TIG welded. The 427/FIA arms are both MIG and TIG welded, depending upon application. Aluminum castings are done locally from AlMag or 356 aluminum. Some of the pieces are machined from billet.

How is the interior done? Everything but the top and car covers are produced in house. |  |

Do you do the fiberglass molding?

|  |

| Dealer information E.R.A. has a very limited network of dealers. We may offer a small discount for multiple purchases within a limited time frame. Since our profit margin is small, this discount is not deep. Call Peter for details. 860-224-0253, 9am-12am, 2:30pm-5pm. |  |

Assembling the chassis and painting the body is straight-forward. Have us powder-coat the chassis and bond the body. It will save you a lot of time, and it isn't very expensive.Rebuilding the rear suspension is fairly complicated. If you don't have Jaguar experience, expect the first one to be "a learning experience". Once you get everything figured out, expect to spend about 12-15 hours on a rebuild, plus parts. If it isn't a limited slip, add about $600.

289/302/351 engines are relatively cheap and easy to build. You can either use an old core, or get new parts from Ford Motorsport, etc. Stay with the Windsor style engine, if possible. The Cleveland may present space and exhaust system problems.

We recommend that you build a single car to acquaint you with the building process before you commit to multiple cars If you do decide to jump in with a multiple order, your deposit on each kit is fully refundable up until the time we start it. You can't lose money on a deposit.

How do I visit the Factory?

You are welcome to drop in any time during business hours - 8am-5pm on weekdays and usually until noon on Saturday. Just be sure to follow these directions. It's easy to get lost in New Britain!

How can I contact ERA?

Peter (our General Manager) can be reached on weekdays by phone, 9am-12am, 2:30pm-5pm, 860-224-0253. You can also fax questions to Peter at 860-827-1055.

You can e-mail us

Sorry, but we can't quote cars via e-mail. It's best to talk to Peter about your requirements. Some sample kits are listed here.

About E.R.A.

How long has E.R.A. been in business?

E.R.A. began in 1968, doing restorations of Porsches, BMW's and several British cars. In the first year, we fixed a totalled 289 Cobra (bought for only $1500 at the time by our current general manager, Pete Portante. The car was sold about 8 years later - before the prices went crazy, of course.

) and a Fiberfab kit car, among other projects. In 1981, we started on our 427 replica. By 1985, all our restoration work ceased - we were just too busy doing our 427. So far, we've delivered over 800 kits to 30+ states and a half-dozen countries.

In 1990 we delivered our first ERA GT.

In 1997 we delivered our first 289FIA.

In 2009 we produced our prototype Slabside, with delivery of the first production kit scheduled for spring 2010.

We currently have around 14 full-time employees. Our workers are approximately evenly distributed among the fiberglass, welding and fabrication, kit assembly, final assembly, R&D, wiring, and office staff, with many wearing several hats each day. We sublet some sheet-metal parts, but the final product is always processed right here.

A SHORT HISTORY OF E.R.A.Era Replica Automobiles is a historical extension of International Automobile Enterprises, Inc. I.A.E. was founded in 1966 with a vision: To develop the necessary skills, expertise and equipment to ultimately produce world class performance automobiles. |